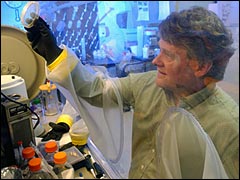

Well before cellulosic ethanol became the hot new fuel, Lee Lynd was immersed in it. Since 1987, the engineering professor has been leading a major academic study group on cellulosic ethanol from his perch at Dartmouth. Before that, he even wrote his undergraduate honors thesis on it.

Lee Lynd.

Photo: Joseph Mehling/Dartmouth

More recently, Lynd has been putting his technical expertise to the test in the marketplace. In 2005, he cofounded Mascoma, a cellulosic biomass-to-ethanol company that has just completed its second round of venture funding with support from Vinod Khosla and other investors. (Lynd serves as chief scientific officer.) In April, Lynd and a colleague announced that they had developed a new, cost-effective method for pretreating cellulosic feedstocks at low temperatures for conversion to ethanol and other marketable byproducts.

Along with his laboratory research, Lynd has advised policy makers on how to advance biofuels, serving on an advisory committee to the Clinton administration, coauthoring studies with the Natural Resources Defense Council and other environmental organizations, advising the National Commission on Energy Policy, and testifying before Congress. Grist spoke with Lynd recently about the prospects for his pet project.

How close do you think we are to producing cellulosic ethanol on a large scale?

I think it’s quite likely that we’ll see construction start on cellulosic ethanol plants in the United States in 2007. How quickly cellulosic ethanol displaces large fractions of our petroleum use will depend on investments and on how quickly the industry grows.

What are the major technical challenges that remain to be solved?

Most of the steps to convert cellulose to ethanol are technically well understood. The big obstacle is overcoming the recalcitrance of cellulosic biomass — it’s much harder to break up than corn is, because cellulose has a different biological function. Corn’s role is to store nutrition above the ground during the growing season. Lignocellulose is made to hold up the plant, so its function is structural, not nutritional, and it has to withstand extreme temperatures underground during the winter. And plants have evolved to resist microbial attack, so they’re harder to attack by nature.

So how do we get at that energy?

The route most people envision is using enzymes or microorganisms to convert the carbohydrate part of the plant into sugars that can be fermented. Eventually we’re going to have microorganisms that grow directly on cellulose and produce the products we want. That’s a bona fide breakthrough opportunity that could come in the near or the long term, depending on how aggressively it’s pursued. There are a lot of opportunities to reduce production costs if we can make progress on pretreatment, and [progress] on biotech to develop microorganisms that can convert cellulose to sugars and ferment it. I’m optimistic.

Have Congress and the Bush administration provided enough funding and policy direction to get us from here to there?

If we do the things that were authorized in the 2005 Energy Policy Act, it would represent a very, very substantial investment and would be a huge step in the right direction. But there’s a huge difference between authorization and appropriation, so realizing that promise means that Congress has to deliver the funding. Also, there is some guidance in the energy bill about the importance of open solicitation and peer review that’s important to engage the potential genius out there and move this thing forward.

Are there steps to promote cellulosic ethanol that could be enacted as part of next year’s farm bill?

In general, it would be nice if cellulosic ethanol didn’t have to compete against subsidized crops as people make choices about what to plant.

A lot of production plants, storage systems, and fueling pumps are being put in place now to expand use of corn ethanol. Will it be straightforward to convert these facilities over to cellulosic ethanol at some point? If it won’t, is there a risk that some of this investment will either be wasted on a transitional fuel or lock us into long-term reliance on corn ethanol?

My hunch is that it will generally be cheaper to retrofit a corn ethanol plant than to build a new one from a greenfield site. And there’s increasing willingness to look beyond corn, even from the entities that have traditionally invested in it.

A large fraction of the new investment in corn ethanol is technology that’s owned by farmer cooperatives, not primarily by the big corn processors like Archer Daniels Midland. The farm community is more ready to listen to ideas about biofuels now than it has ever been because of the price of oil, national interest in energy, and the entry of the venture-capital community. They don’t want to be left out, and if they have to change to new fuels, they’ll change.

What do you see as the most promising cellulosic ethanol feedstocks — switchgrass, fast-growing trees, or other sources? Would it make sense to focus federal R&D on a few choices, or should we pursue lots of options at once?

I think we can let the market work out the feedstock conversion side. But we’re very under-invested in everything to do with cellulosic biomass feedstock production. We need to do more to develop new crops and cropping systems.

Cellulosic ethanol is getting a lot of buzz from big-name investors like Vinod Khosla and Richard Branson.

In the past year, high oil prices have convinced the venture-capital community that there will be a market for this technology. Now they see it as one of the most attractive investment magnets out there. That’s a new climate, and I’m still adjusting to it myself. But government funding is also useful — it can leverage private money, and federal agencies can clear up lingering issues like growing corn for food versus for fuel, or whether ethanol produces a positive energy balance.

You clearly think the U.S. can and will transition from corn ethanol to cellulosic fuels. What else do you say about ethanol to people who are concerned about environmental impacts?

As recently as three to five years ago, most environmental advocacy groups were at best ambivalent about biomass fuels. That’s changed pretty dramatically. Organizations like the Natural Resources Defense Council and the Union of Concerned Scientists are saying that cellulosic ethanol is at least as promising as a hydrogen strategy for the future, and that it offers game-changing environmental benefits, manageable technology, and no showstoppers if we have the will to develop it. All of us who are providing input on this issue have to be careful that we don’t get too attached to our old analyses.