Among all of the terrible ways to get rid of nuclear waste, there’s one that stands above the rest for being a little less horrible: turning the radioactive parts into glass, a process called “vitrification.” Unlike other glass, you really need to be vigilant about NOT drinking Scotch out of it. But the advantage of nuclear-waste glass is that it stays stable for a long, long time, and it does not leak.

Contrast that with the storage tanks at Washington State’s Hanford Site, where the U.S. made bombs — including the plutonium for the very first nuclear bomb — all through World War II and the Cold War. There’s 56 million gallons of chemical waste in those tanks, some of which are leaking. And you can’t drink Scotch out of those either, so: lose-lose.

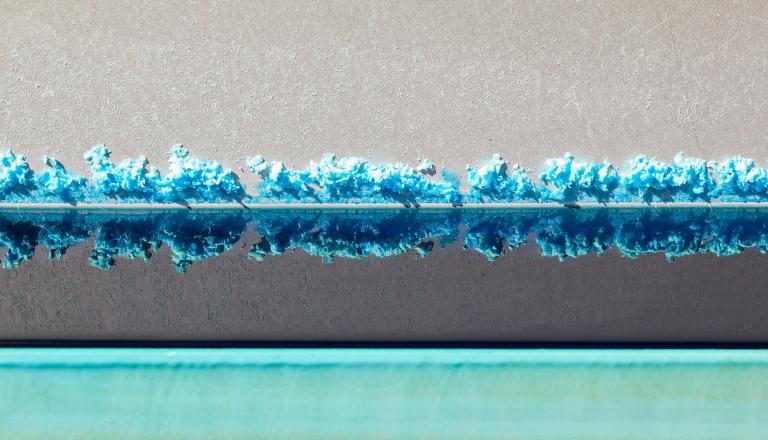

As the Wall Street Journal reports, Kurion, Inc., a startup that helped clean up nuclear waste at Fukushima, is starting a project to clean up the site by trapping the radioactive particles in glass. The company filters liquid waste through an “ion specific media” that traps the bad parts and that can then be melted into glass.

Vitrification’s not a new idea — Europe, for instance, has been doing it for a long time — but it’s pretty expensive to pull off. As GigaOm reported earlier this year:

Kurion’s business model is to make the nuclear clean up process more distributed, more flexible and more low cost. Traditionally vitrification has been a more centralized process.

No matter what technique is used to clean up nuclear waste, the end result is still terrifying radioactive matter. But radioactive glass, formed in steel canisters and buried, does seem preferable to gigantic tanks of sloshing, liquid nuclear waste.