The rig operator was stumped. He’d been making good progress, but now something blocked the way forward. The operator, Denny Mong, stared at an unassuming metal tube in the ground — the fossil of an oil well. Spread around it was an array of industrial detritus and steel tools like giant surgical implements, which sunk into the spongy Western Pennsylvania meadow.

Above the hole, Mong’s rig, which towered 50 feet into the air, suspended a vertical ramrod. When it dropped, the ramrod only shot 17 feet into the ground before slamming to a stop. Earlier, Mong had managed to reach more than 500 feet deeper into the well. Then this obstruction, whatever it was, sent him back to the start.

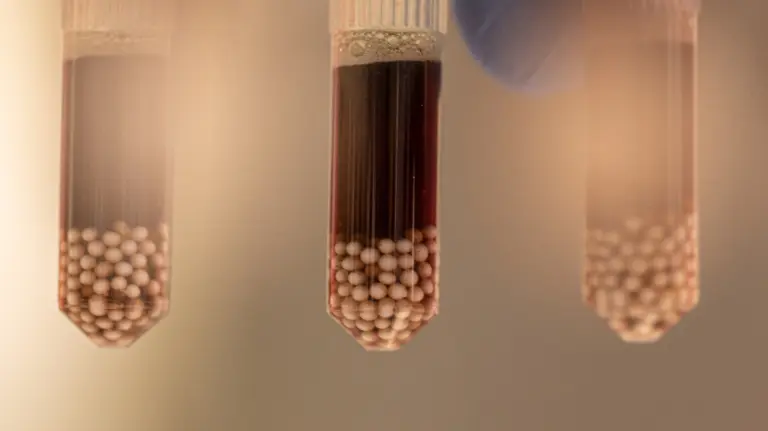

Clearing it — prime suspects included metal casing, rocks, or a tree branch — would allow him to send cement and pea gravel into the hole, which reached hundreds of feet into Appalachian rock formations. Once an active oil well, now it was an environmental nuisance and the target of an ambitious federal cleanup program.

The well needed to be decommissioned, along with at least 21 more spread across woodlands and fields in McKean County, Pennsylvania. The job fell to Mong and other employees of an oil service outfit called Plants & Goodwin, which specializes in plugging so-called orphan wells. Oil and gas companies are supposed to plug and clean up wells that they’ve drilled, but if they go bankrupt or otherwise disappear, that responsibility falls to the state, which then contracts with companies like Plants & Goodwin. If left festering, these wells can leak contaminants into surrounding groundwater or release methane, a greenhouse gas at least 25 times more powerful than carbon dioxide at trapping heat in the atmosphere.

Uncorking a well in this part of Appalachia reveals a blend of oil and gas that has a nauseous maté color and gurgles like witch’s brew. After generations of drilling, the remnants of both vernacular backyard digs and professional oil operations pockmark the land. Since drillers operated for more than a century with little regulatory oversight, documentation of well locations is scarce and cleanup quality is inconsistent.

“Until the 1970s there were no strong plugging standards in place,” said Luke Plants, who heads Plants & Goodwin. “People just shoving tree stumps down a well to plug it, or a cast iron ball or something like that.”

The exact number of orphan wells nationwide is unknown. In late 2021, The Interstate Oil and Gas Commission, a multi-state organization, had more than 130,000 orphan wells on record but estimated that anywhere between 310,000 and 800,000 remained unidentified. That year the federal government took notice, folding $4.7 billion into the Infrastructure Investment and Jobs Act to help states handle their orphan well inventories. The first batch of that money has trickled down to states and has been distributed to contractors like Plants & Goodwin. It’s easily the most funding ever spent to address the problem, but both states and pluggers are now facing hurdles as they begin to identify and plug wells.

The state oil and gas regulators responsible for issuing well-plugging contracts are typically understaffed. As a result, the pace of contract assignment in some states has been inconsistent, making it difficult for plugging companies to staff up and plan ahead. Well pluggers are also few and far between. Since oil operators tend to avoid the costly work of well capping, the service has remained a niche industry. Plugging companies have also struggled to find trained workers, not to mention the specialized equipment required to plug wells. Along the way, some states have handed out millions of dollars in contracts to a subsidiary of an oil company with hundreds of compliance violations.

All the while, the oil and gas industry continues to spawn new orphan wells — magnitudes more than the number being plugged. Between 2015 and 2022, more than 600 oil and gas companies filed for bankruptcy, leaving thousands of wells unplugged. Market downturns affecting oil prices during the mid-2010s pushed many operations to insolvency. And even in times of industry booms, wells near the end of their production lifespans often end up in the hands of small oil patch operators with tight margins. Further, state laws requiring companies to post collateral for their wells in case of bankruptcy are meager. This combination of weak rules and bankruptcies has caused orphan well inventories to balloon. For example, Pennsylvania’s list of 20,000 orphan wells grows by about 400 each year; the state has plugged just 73 wells with the federal money that began to arrive last year.

In the muddy pasture in northwest Pennsylvania, Mong was trying to unclog his way to the well’s bottom. Using a rig attachment called a cherry picker — imagine a four-foot steel clothespin — he worked to spear unknown detritus from the depths. Next to the hole lay 30-foot-long clay-frosted tubes of steel casing already hauled out. After reducing the borehole to a hollow dirt cavern, the pluggers will pour cement until it nearly fills to the surface and top the rest of the way with gravel, insulated by steel casing to protect groundwater. They will then decapitate the casing to a few feet below ground and cover it with dirt.

For the pluggers, the work is a bespoke combination: a little science and a lot of art. Sharp intuition, engineering know-how, grit, and luck imbue each effort. One capping can take anywhere from three days to three months, sometimes costing more than $100,000.

A lot needs to happen to orphan wells before they’re plugged — at least on paper. The state has to identify them, the threat they pose, the costs to plug them, and search for any elusive owner to pin the costs on. And while that’s a process states have handled for many years, most state plugging programs have relatively small budgets and staff compared to the well inventories. Now, federal funding is compelling those programs to exponentially increase the number of well-capping contracts, an impossible task without bigger staffs and nimbler processes.

In a normal year, the California Geologic Energy Management Division (CalGEM), which regulates oil and gas production in the state, might contract plugging for 30 wells. According to former CalGEM employees, decommissioning even that number of wells had the agency running on all cylinders.

“Available staffing for oversight was definitely a major limiting factor,” said Dan Dudak, who was the Southern District Deputy of CalGEM from 2011 to 2020, and now acts as a consultant on well-plugging projects. In just the last five years, the department “lost a lot of their institutional knowledge” in three different leadership changes, he said. Nonetheless, CalGEM revealed an $80 million project last July to cap 378 wells with funding from state and federal money along with industry fees.

Other states also have catching up to do. One 2022 Ohio state audit observed that its Department of Natural Resources struggles to meet orphan well program spending targets, in part due to staffing shortages. “[T]he Division can only increase efforts dedicated to well plugging preparation work as fast as it can recruit, train, and hire permanent employees,” the audit claimed, recommending that the agency double its staff to post plugging contracts in a more timely fashion and consider outsourcing the task of drafting contracts.

Pennsylvania has 70 well inspectors and a tally of around 20,000 orphan wells. According to Neil Shader, spokesperson for the state Department of Environmental Protection, or DEP, the agency is considering hiring more inspectors to increase its oversight. Earlier this year, the state legislature approved a $5.75 million budget increase for DEP, some of which may boost its well plugging contract capacity.

Still, the pace of contract creation in Pennsylvania has put pluggers in a precarious place. Plants said that when Pennsylvania received $25 million in its first batch of federal funding, he staffed up. A torrent of contracts were awarded but then stopped — leading from feast to famine. A six-month gap meant furloughs and mothballing equipment. “It costs contractors a tremendous amount of money to do all that,” he said. “You end up creating an incentive to not scale at all, just stay small.”

To expedite aspects of the contract-drafting process, DEP has signaled that it may outsource some of that work. Meanwhile, Ohio is putting some of its federal money into an expedited process called the Landowner Passover Program, where approved landowners who find orphan wells on their land may act as a surrogate for the state, awarding a contract to a plugger that Ohio will pay for.

Ohio has 44 contractors on its rolls and utilizes a pre-approval process for its pluggers to maintain quality control. Pennsylvania’s DEP is considering adopting its own vetting process, according to Shader, the agency spokesperson. Without it, there is no central parapet to separate under-qualified contractors from federally funded plugging. “There are not enough defined rules in place,” said Plants. “And even the rules that are there don’t get followed so well all the time.”

Not much stands in the way of a corner-cutting contractor. In remote pockets of Appalachia, improperly dumping chemical fluids from a site or shoddy plug job could go unnoticed. “I think it’s even less likely to get checked now,” Plants said. “Because nobody wants to limit the pool of potential well pluggers. We need to get more pluggers involved — whether that plugging is being done correctly or not.”

Last year, Pennsylvania Deputy Secretary Kurt Klapkowski of the DEP’s Office of Oil and Gas Management addressed that anxiety by announcing that parties with significant outstanding violations, such as contractors with a poor service record or operators with environmental infractions, wouldn’t receive state contracts. “I feel pretty confident that we would not be issuing contracts to operators that had significant outstanding violations — either on the contracting side of things or on the environmental protection side,” he said.

For a plugger, non-compliance could mean illegal dumping or improperly sealing a well; for an operator, it might mean abandoning a well without plugging it. But such policies can be difficult to implement when oil and gas companies sometimes operate through a bevy of subsidiaries in multiple states.

In December of last year, the Pennsylvania DEP awarded Next LVL Energy contracts to plug 30 wells in the state. The company is a subsidiary of Diversified Energy, an energy giant that has amassed a massive number of wells at the end of their lives, stoking fears that the company is likely to orphan them. According to one class action lawsuit against Diversified in West Virginia, around 10 percent of its 23,309 wells in the state are technically abandoned but unplugged. Just this year Pennsylvania inspectors slapped the operator with around 300 new or unresolved operational violations. (The state DEP didn’t respond to a request for comment on Next LVL’s contracts.)

Ohio has also given half of its first installment of federal money, $12.5 million, to Next LVL Energy to oversee the plugging of as many as 320 wells. To the southeast, West Virginia has given the company a similar sum to plug 100 wells. Spokespeople for both state environmental agencies defended their decisions, noting that they followed state and federal guidelines while selecting pluggers. “We will keep a close eye on implementation,” said Andy Chow, a spokesperson for the Ohio Department of Natural Resources. “Should any violations in this contract be discovered or otherwise come to our attention we will review those actions.”

In West Virginia, Next LVL isn’t plugging any wells associated with Diversified, according to Terry Fletcher, chief communications officer with the state’s Department of Environmental Protection. “At the time the contracts were awarded, Next LVL had no outstanding environmental violations in the state,” he added.

Finding qualified workers for the oil field is no easy feat, either. The last decade has seen drops in oil prices that rendered many fossil fuel companies insolvent, along with a shift to shale exploration, which requires fewer workers. As a result, job openings have dwindled and many qualified workers have left Appalachia.

Plugging wells also requires skilled labor. Thus, the limited number of qualified workers is in high demand. That’s good for wages, but without a large workforce to fill positions as states push out contracts with increasing frequency, another problem arises: “You just get this arms race for the same small pool of workers,” said Plants. “That’s not actually helpful for scaling or expanding the supply side of this business.”

Plants has brought in experienced pluggers from Texas oil fields to help train up a new generation of skilled Pennsylvania hands. “We want to develop a local workforce that understands this work,” he said. But “you can’t just put whole crews of inexperienced people out there.”

There’s a lot of on-the-job training, but that extra work advances his vision. Some of his most recent hires came from area high schools and technical schools, where he has made a pitch: “We want to give you a long-term career.”

Bronson Knapp, who owns Hagen Well Services in Ohio, has faced similar challenges. “The good old farm boy is hard to find,” he said. A worker shortage is one of the reasons Ohio is behind on well pluggings. The state has awarded new contracts even as work from previous contracts hasn’t been completed. “We awarded 380 wells this year, but our contractors are still 400 wells behind us,” said Jason Simmerman, the orphan well program engineer with the state’s Department of Natural Resources.

Rigs used to plug wells can be hard to come by, too. Drilling technology may advance, but orphan well-plugging is frozen in time. The tech required is often vintage, which means pluggers are on the prowl for a shrinking number of rigs that may be older than the wells they plug. It’s not unusual for a plugger in New York to look as far as Texas for a used rig. Mong’s rig was from the 1950s. Another rig at a nearby work site was manufactured in 1981 and welded to the bed of a Vietnam War-era military truck.

On the whole, a few recent high school graduates on Plants’ payroll might not seem like bellwethers of a next-generation workforce. But some experts watching the federal orphan well program contend that a well-plugging wave could revive regions whose economic fates are tied to dwindling resource extraction sectors. “The most positive thing that could happen is that we begin to get more companies plugging wells, especially in rural, distressed areas to help their local economies,” said Ted Boettner, a senior researcher at the Ohio River Valley Institute, a think tank focused on economic and environmental sustainability in Appalachia.

“Oil and gas industries have lost thousands of jobs over the last decade,” he told Grist. “This is helping people who lose their jobs” and providing “a way for people to transition into cleaning up this mess of the last 150 years.”

The federal program includes requirements and guidance to help ensure that the work on the ground benefits workers. In order to qualify for funding, states must ensure that plugging contracts meet standards outlined by the Davis-Bacon Act, a federal law that guarantees government-funded labor matches average pay rates for similar work in a region, known as the prevailing wage.

Failure to follow the federal government’s requirement risks its scrutiny. For example, last year the GOP-led Pennsylvania legislature passed a law dictating how much a contractor might receive to plug a well as part of Pennsylvania’s orphan well program. The amounts allocated were a fraction of typical costs, likely leaving contractors unable to pay their workers the prevailing wage. With federal money tied up in the program, the Department of Interior filed a brisk response warning that the law could threaten Pennsylvania’s ability to comply with program standards and that the state could be cut off from federal funding.

In Ohio, Davis-Bacon requirements appear to have an effect on well-capping work not funded by the federal program. Though the Buckeye State doesn’t have any wage requirement for general well-plugging work, cappers who have taken contracts appear to be paying higher wages — whether or not the job is federally funded. “Because nobody wants to make one wage one day and another the next day, our contractors that are working on our federal program are taking that perspective and paying those wages across the board now,” said Simmerman, Ohio’s orphan well program engineer.

Out west, California is working to nurture a workforce at a much larger scale. Last year, the state legislature passed a law directing the California Workforce Development Board, or CWDB, to launch apprenticeship programs to train new classes of well pluggers. It could become a model for skilled labor creation. Its first pilot program is using the expertise of a Kern County well-capping company, California Legacy Well Services, which is creating a plugging curriculum to fold into existing training provided by Local 12, the International Union of Operating Engineers. As a result, union-affiliated labor will represent part of the well-plugging workforce.

The thinking is two-pronged: access to quality jobs and layoff mitigation. That means offering good work to skilled laborers vulnerable to the energy transition. “So rather than just worry about the loss of jobs, it’s an opportunity to think about the new jobs for trades workers,” said Tim Rainey, executive director of CWDB. The program is in the early stages, but it offers a glimmer of what an effective orphan well program could yield.

Organized labor in California’s oil fields is of two types: industrial unions and trades unions. Members of industrial unions cultivate skills on a worksite, while trades unions learn the ropes through training apprenticeships like the ones CWDB is developing.

A quirk in California law may lock out the industrial unions. The law requires “a skilled and trained workforce” for capping jobs, an innocuous-sounding phrase that refers to highly technical requirements in the state labor code that disqualify oil workers from industrial unions such as the United Steelworkers, or USW.

Norman Rogers, a spokesperson and member of USW Local 675 in Southern California, called the legislative sleight of hand “a control job.” Trades unions “have a larger workforce and are able to influence the political landscape,” he said. “They can have all sorts of people go to lobby.”

By expanding the language to characterize eligible workers as “skilled and trained or covered by a labor management agreement,” the law could tap into tens of thousands of union workers represented by USW, Rogers said.

The question of who dominates the green jobs of tomorrow remains an open one. Despite the many bottlenecks, the orphan well program could be an attractive coda to the fossil fuel era if it benefits workers.

“We drilled the first oil well in America,” said James Kunz, an administrator at the Pennsylvania Foundation for Fair Contracting, who has worked to ensure favorable wages in state capping contracts. “We have the scars of that and a real opportunity.”

Correction: A previous version of this post misidentified a piece of construction equipment in a photo caption.