This is part of a series of posts on distributed renewable energy that will be posted to Grist. It originally appeared on Energy Self-Reliant States, a resource of the Institute for Local Self-Reliance’s New Rules Project.

When discussing centralized vs. decentralized solar power, there’s an inevitable comparison between solar thermal electric power and solar photovoltaic (PV). But the fact is that solar thermal power — or concentrating solar power (CSP) — can also be done in a distributed fashion.

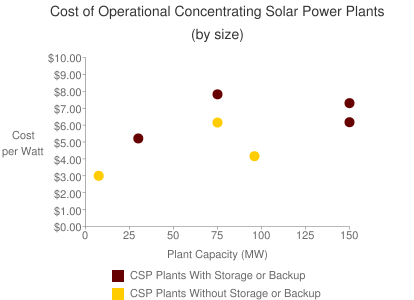

In fact, of the 21 operational CSP plants in the world, 18 are smaller than 80 megawatts (MW). And among operational plants with publicly available capital costs, there’s no clear pattern of lower costs per watt installed for larger projects.

The common element in thermal concentrating solar power is that rather than directly converting sunlight to electricity (solar PV), they concentrate sunlight with mirrors to heat a fluid, and that heat is converted to useful energy. There are a variety of designs for CSP plants, including parabolic troughs, towers, Stirling dish engines, and Fresnel lenses. Because three of the four designs (excluding the Stirling dish) generate electricity from steam turbines, the assumption is that bigger is better, capturing more economies of scale.

But the evidence suggests that most economies of scale are captured at a relatively small size. The above chart explores the cost of CSP plants by size, differentiating plants with storage or natural gas backups from those that are solely solar powered. Rather than seeing declining costs for scale, we see costs leveling or increasing.

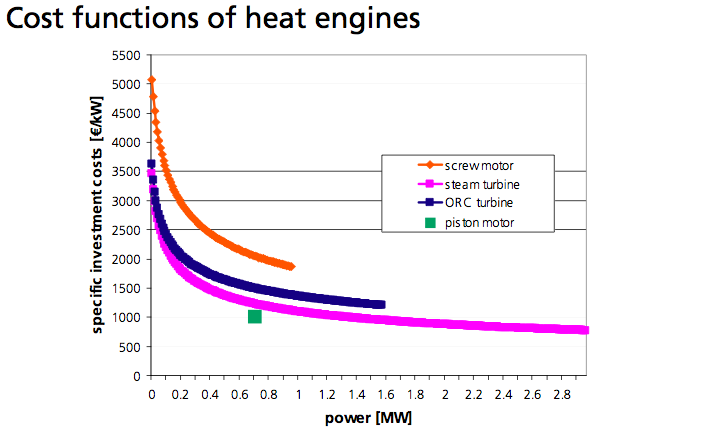

The poor returns for scale may have to do with the limited economies of scale in heat engines (the tools for converting heat to electricity). The following chart illustrates the cost functions of several heat engines (including traditional steam turbines, screw motors, Organic Rankine Cycle engines, and piston motors).

As the chart shows, the cost of heat engines per kilowatt (kW) of capacity drops rapidly as size increases up to one megawatt (MW). But beyond that, the economies of scale are much smaller. For example, there’s only a 100 euro drop in the cost per kW for a steam turbine when increased in size from two to three MW. If the turbine represented the entire project cost, the savings from the larger turbine might equate to a 1 cent per kWh drop in the price of electricity from the project over its entire lifetime. In reality, the turbine is less than 20 percent of project costs and the savings would be much smaller.

In other words, economies of scale are small for CSP projects, even at relatively small sizes.

Perhaps more interesting than the economies of scale of the heat engines is the difference between traditional steam turbines and Organic Rankine Cycle (ORC) turbines. ORC turbines can operate efficiently at lower temperatures, allowing for a smaller field of solar collectors and for CSP plants to populate areas with lower direct solar irradiance. The potential to serve a wider geographic area was noted in a recent interview with the CEO of Sopogy, a producer of “microCSP” (1-20 MW power plants) using ORC turbines:

The Sopogy system doesn’t need high DNI (Direct Normal Irradiance)…according to Kimura. [Traditional CSP] needs 7 plus DNI but Sopogy can work at 5 DNI. That means Sopogy can and is installing systems in the Pacific Northwest, Idaho, the Middle East, Spain and Australia.

In other words, smaller-scale CSP projects may be able to capture most economies of scale and distribute the use of concentrating solar power to areas previously thought uneconomic for concentrating solar. The smaller scale may also prove advantageous because CSP can provide high efficiency heat for industrial use as well as electricity, reaching significantly higher capacity factors (as with traditional combined-heat-and-power facilities).

Overall, the lesson with CSP seems similar to that of solar PV and wind. Most economies of scale are captured at smaller sizes, allowing projects to integrate more easily into existing grid infrastructure.