Picture a liquid fuel that is derived from the same feedstocks as cellulosic ethanol (switchgrass, sugar cane, corn stover) but contains 50% more energetic content and is made via a process that uses 65% less energy.

Unlike cellulosic ethanol, this fuel can be distributed via existing oil pipelines rather than gas-hogging trucks and trains, dispensed through existing gas stations rather than specialized pumps, and used in existing engines rather than modified "flex-fuel" engines.

In short, it is a biofuel that can be substituted directly and immediately for gas or diesel, on a gallon-for-gallon basis.

Sounds pretty good, eh? Too good to be true?

An outfit called  LS9 says it can create such a fuel, and that it can do so at a cost competitive with gasoline, without government subsidies. The company, which was founded in 2005, is making a few key announcements this morning.

LS9 says it can create such a fuel, and that it can do so at a cost competitive with gasoline, without government subsidies. The company, which was founded in 2005, is making a few key announcements this morning.

First, it will be releasing, at least in schematic form, the details of the science it’s using. Stephen del Cardayre, VP of Research & Development, will be at the annual meeting of the Society for Industrial Microbiology to present some of the technical details (on those, see below).

Second, it’s announcing the hiring of Robert Walsh as its new president. Walsh is an old-school oil guy — 26 years at Royal Dutch Shell, where most recently he managed Shell Europe Oil Products, to the tune of some $30 billion in revenue. Not your starry eyed green idealist. Walsh says:

After years of leadership roles in the traditional petroleum industry and responsibility over all aspects of the hydrocarbon supply chain, I can see clearly how LS9’s products will fit into existing infrastructure and deliver significant value to partners and consumers compared with other biofuel alternatives. LS9 has the opportunity to fundamentally change the transportation fuel equation, which makes me incredibly excited to join this talented team.

LS9 plans to build a manufacturing facility in 2008 and have products available at commercial scale within 3-5 years.

All of which is to say: these are not idle claims.

What are these fuels, and how will LS9 make them?

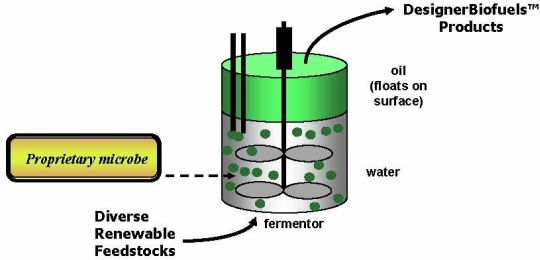

The process is the same as making cellulosic ethanol insofar as cellulosic feedstocks are converted into fermentable sugars, and those sugars are placed in a fermentation vat. The difference comes in the microbes doing the fermenting. With ethanol, it’s generally some form of yeast. The researchers at LS9 have engineered their own microbes, lifting genes from other microbes and recombining them into an organism that does just what they want. In this way they can precisely tweak the characteristics of the resulting fuel.

Yeast fermentation produces ethanol, which mixes with water and subsequently has to be extracted via distillation. LS9’s microbes produce — via fatty acid metabolism, in a process I won’t claim to understand — hydrocarbons (the building blocks of petroleum). These hydrocarbons are immiscible, i.e., they don’t mix with water. Instead, they float to the top of the vat, where they can essentially be skimmed off. That allows LS9 to skip the distillation process, which saves a whole boatload of energy. (That’s where most of the claimed 65% energy savings comes from.)

LS9 claims that by tweaking its microbes it can produce "designer biofuels" that are, in the lingo, "fit for purpose." That is to say, they can be matched precisely to the required use. One product is "bio-crude," which can substitute directly for crude oil — it can be refined into gas or used to make all the many petroleum products we know and love, like plastics, fertilizers, etc. Other products can go directly into tanks, including bio-equivalents to gasoline, diesel, and even jet fuel.

Chemically speaking, hydrocarbons are hydrocarbons — LS9’s products are essentially identical to their fossil-based counterparts. They can do whatever oil products can do, without the need for special equipment.

Can you be more concise?

Sure. LS9 has genetically engineered microbes that will eat sugar and crap oil.

What are we greens to make of this?

As far as greenhouse-gas emissions, the news is mixed. In terms of pure combustion — i.e., what comes out of the tailpipe — LS9’s fuels are about the same as gasoline. (By comparison, E85 — 15% gas, 85% ethanol — is about an 80% emissions reduction from gasoline.) However, the company claims that on a lifecycle basis, its products represent a reduction in GHG emission from both gas and ethanol.

Why? Relative to gas, LS9’s products don’t require drilling for oil. They don’t release any previously buried carbon into the atmosphere. Instead, the feedstock plants absorb CO2; it’s released when the fuels are burned; it’s reabsorbed by the plants; released again; etc. In other words, it’s a closed loop, recycling CO2 already in the atmosphere.

Relative to ethanol, LS9’s products don’t require a huge new distribution infrastructure. Ethanol, if and when it scales up, will be distributed by lots and lots of trucks and trains, which will be burning lots of gas and emitting lots of CO2. LS9’s products can be distributed via existing oil infrastructure. That saves gas.

Also, LS9’s products have roughly double the energetic content of cellulosic ethanol, which means they require half as much feedstock for the same amount of oomph. That reduces the amount of feedstock crops necessary, thus reducing industrial agriculture and all its attendant ills.

Another advantage over cellulosic ethanol is that LS9’s process can create a crude oil substitute that can be used to make petroleum-based products. That means we could get the oil out of those products immediately, without having to reconfigure the production process to make use of carbohydrate-based materials.

Incidentally, LS9 says that while its fuel will be roughly equivalent to gas in terms of nitrogen oxide (NOx), it will have only trace amounts of sulfur, so no SOx. It will also have much less benzene and other toxic compounds found in gas.

I know there are greens who feel creepy about genetic engineering, and they probably won’t like the fact that LS9 is trying to patent a life form. But I don’t really share those concerns, so I’ll just skip them.

Can you be more concise?

Sure. "Renewable petroleum" — yes, that’s what they call it — strikes me as vastly preferable to liquid coal and corn ethanol, substantially preferable to cellulosic ethanol, and inferior to a transformed society based on dense cities, public transit, and electrified transportation using renewable sources.

Conclude already.

We have an enormous infrastructure built up around liquid fuels, so even if you want to eventually get rid of them — and I do — you need ways to reduce oil use and GHG emissions while you’re working toward that goal. LS9’s biofuels can be plugged into our oil infrastructure immediately and could, if widely adopted, radically reduce the use of imported oil.

All of this assumes, of course, that LS9 can make good on its claims. That’s still a huge assumption.

We’ll find out soon enough.

(Thanks to Greg Pal at LS9 for talking me through the details.)