Todd Loose of Waste-Not Recycling holding chunks of metal salvaged from used ski gear. (Photo by Joshua Zaffos.)

You don’t need to spend much time on the slopes to know that winter sports enthusiasts are the ultimate gearheads. Beyond the outrageous fashion fads (neon one-piece, anyone?), design and technology breakthroughs allow manufacturers to roll out more lightweight and higher-performance gear every season.

The steady advances are great for bombing down runs on powder days and pretending you’re Lindsey Vonn. But the heaps of old skis, snowboards, and boots that get tossed into garages, sheds, and trash piles are a wasteful legacy. Notwithstanding niche craftsfolk who turn their share of old skis into fences and Adirondack chairs, much of this stockpile is destined for the landfill.

Greg Schneider is well aware of the problem. As recycling program manager for Snowsports Industries America, an industry trade group, Schneider has spent three seasons collecting castoff equipment from a handful of retail outlets in Colorado and Utah, and he’s already built up a 300-ton massif of ancient gear.

His next challenge? Finding a use for the stuff.

A former ski instructor, Schneider began his quest to repurpose spent snow toys in 2008. He originally worked with a Canadian company to figure out how to break down skis and other gear into usable parts. But when the company went out of business, it was back to square one. Goodwill provided Schneider with a place to store his mountain of forsaken gear in a warehouse in Denver, while he took another run at the issue.

Finally, in 2010, Schneider connected with a company in Loveland, Colo., called Waste-Not Recycling. Using state grant money raised with landfill-collection fees, the partners researched and then acquired equipment for a disassembly line. The row of equipment looks a little like a contraption out of Willie Wonka’s factory, except instead of spitting out candy, it turns out bits and bolts of aluminum and other metals, separated with magnets, and shredded ribbons and pieces of plastics and composite materials that can include fiberglass, carbon fibers, and even Kevlar.

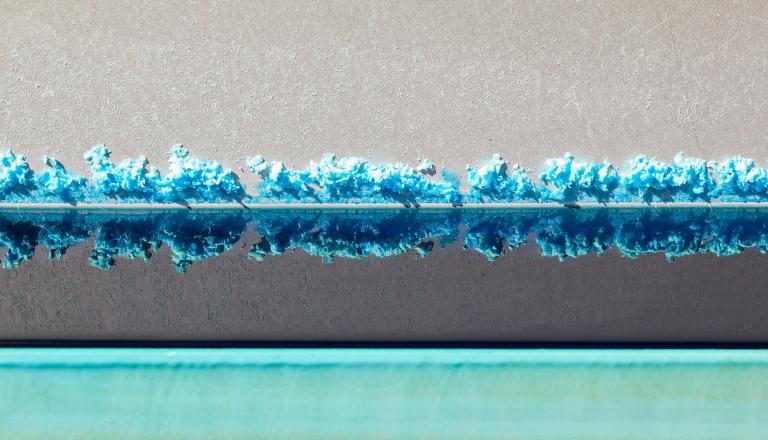

This is what 300 tons of old ski gear looks like. (Photo by Greg Schneider.)

Once they have the process mastered, the team wants gear makers to close the loop and recycle old equipment into new items. In addition to one day making new snowboards out of old ones, they imagine turning discarded gear into shelves for retail displays or decking at resort areas. To support the recycling program, participating retailers ask customers to pay a voluntary fee — $1 for new skis or a snowboard, and 79 cents for a rental.

Schneider recently shared progress on the initiative with product manufacturers at the Snow Show in Denver, the largest annual snow sports industry trade show. “There’s a core group of manufacturers that are very interested in sustainable design,” he says. “We’re gaining traction now. We’re on the cusp of breaking this open.”

But even if the industry did commit to recycling old gear, Schneider could only handle a tiny fraction of what gets thrown away each year. The crew at Waste-Not is still learning how to efficiently run and power the processing line, and the larger goal of repurposing materials into new gear is still at least a few years away.

Schneider plans to expand collection efforts to include major retailers in Boise and Albuquerque and ski areas around Park City, Utah, and Breckenridge, Colo. But with processing moving ahead slowly, collection will have to expand gradually — lest a Goodwill warehouse employee gets buried under a mountain of sweat-stained boots and old skis.

Asked for a ski analogy, Schneider deadpans: “We’re moving on from the bunny hill.”