Part 2 of Grist’s special series on poop.

“We’re trying to get the pieces bigger — ideally the size of pencil erasers,” said John “Rus” Miller, handing me a plastic packet of a brown, dry, crumbly material with the texture of couscous and the odor of manure. That’s because it was manure — in the form of dried sewage sludge. To me, it looked and smelled like shit. But when Miller looked at the pellets, he saw coal.

I was visiting a company named Enertech‘s plant in Rialto, California, because I was searching for alternatives for what we currently do with sludge — the dark brown, complex material that’s left over after wastewater is treated. Referred to as “biosolids” by the sewage industry, more than half of America’s sludge is applied to land as a soil amendment or fertilizer. However, since sludge also contains thousands of chemicals, pharmaceuticals residues, and other toxic materials that get dumped into our sewers, many call this more of a problem than a solution.

But what if we could use sludge as energy? In addition to undigested food, it contains woody material from toilet paper and billions of microorganisms from our digestive tracts and the plants where sludge is treated, all of which contain carbon. Sewage treatment plants have captured methane from their sludge for years, which can either be sold or used to run the plant — but those systems only partially reduce the volume of the sludge that’s left over. So far there’s no widespread method to create energy and get rid of the sludge at the same time.

You’d think this wouldn’t be the case. Back in 1873, before most American cities had sewer systems to begin with, Scientific American commented that “(i)t is no exaggeration that the problem of the conversion of the excremental waste of towns and people and the refuse of factories into useful materials is now engaging as much of the attention of intelligent minds throughout the world as any social question.”

Other social questions trumped sewage, though, and it’s only been recently that the cost and controversy of our current methods has inspired a new generation of intelligent minds to look for alternative solutions. Some of these, while exciting, are still embryonic, like fuel cells that use sewage-eating microbes to produce electricity, closed-loop incinerators that run off of sludge and waste oils, biofuel made from sewage-fed algae, or methods that gasify sludge into liquid fuel. But a handful of promising alternatives are already in use. One of them is SlurryCarbTM.

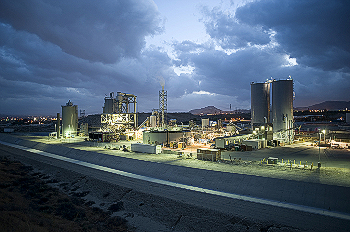

Enertech’s plant in Rialto, California, is producing a biofuel from processed sludge.Courtesy EnertechThe theory behind SlurryCarb is not particulary complicated: take sludge, dry it into pellets, then burn it as a carbon-neutral replacement for coal. And in fact, when I first saw Enertech’s Rialto Plant, I wasn’t particularly impressed. Flanked by a sewage treatment facility and a cement manufacturer, it blends in perfectly with its industrial surroundings. Large silos of sludge feed into an outdoor network of metal pipes; eventually, the sludge goes through a centrifuge and heat dryer and comes out as pellets on the other end.

Enertech’s plant in Rialto, California, is producing a biofuel from processed sludge.Courtesy EnertechThe theory behind SlurryCarb is not particulary complicated: take sludge, dry it into pellets, then burn it as a carbon-neutral replacement for coal. And in fact, when I first saw Enertech’s Rialto Plant, I wasn’t particularly impressed. Flanked by a sewage treatment facility and a cement manufacturer, it blends in perfectly with its industrial surroundings. Large silos of sludge feed into an outdoor network of metal pipes; eventually, the sludge goes through a centrifuge and heat dryer and comes out as pellets on the other end.

But while the idea of burning sludge is simple, there’s a big problem: when it arrives from the wastewater treatment plant, sludge is really, really wet. Treated sludge looks like clumpy dirt but it’s actually 70 to 85 percent water, much of which has to be removed before the sludge will burn. Adding to the challenge, a lot of the liquid in sludge is locked within its cell walls. Releasing that trapped liquid takes so much energy that although plants have been pelletizing sludge for years (usually to use as fertilizer), there’s a net energy loss.

That’s where Enertech is different. Unlike a traditional heat-drying plant that uses evaporation to get rid of water — which requires a lot of energy — Enertech pressurizes its sludge so that it never boils. Then it uses controlled heat to break down the sludge’s cell walls and force them to release their water. Enertech’s overall process uses less than half as much natural gas as a traditional drying plant and produces what the company claims is a net energy gain of approximately 95 percent. Granted, that gain doesn’t take into account the energy the wastewater treatment plant used to dewater the sludge before it got to Enertech. But the system works well for Enertech’s balance sheets: not only do the treatment plants take care of some of the drying beforehand, but they have to pay Enertech a tipping fee for every ton of sludge that it accepts.

At full capacity, Enertech hopes that its Rialto plant will produce 200 dry tons of SlurryCarb per day, which prompts the obvious question of what they’re going to do with it — in most markets, dried shit doesn’t go for much. Luckily for Enertech, the answer is right next door: cement plants. Making cement produces a lot of carbon dioxide, and most cement plants run on coal — and ever tightening regulations make cement plants eager to find substitutes for the coal in their kilns. SlurryCarb, which is cheaper and has about half of the BTUs of bituminous coal, is exactly that. (It’s also a hell of a lot easier to extract.) Even better, sludge’s leftover ash contains silica, another ingredient in cement, and can be incorporated directly into the cement mixture. Cement plants therefore don’t just reduce the volume of the sludge by burning SlurryCarb — they make it disappear.

So far, Enertech has contracts with two cement companies in Southern California, and is in talks with five more. Its technique has also attracted foreign attention: the Masdar Clean Tech Fund is considering hiring Enertech to handle the biosolids produced by Masdar, a planned development in Abu Dhabi for 50,000 people that aims to be the world’s first carbon-neutral city. Back home, Miller says he’s spoken with sewage agencies in most of America’s major cities, who are watching the Rialto plant with interest. If it’s a success, Enertech hopes the SlurryCarb process might become a common way for sewage treatment plants to dispose of sludge.

“But what if you eventually produce so much that the SlurryCarb gets used in places besides cement plants?” I asked Miller when he explained that SlurryCarb could be used in other industries as a substitute for low-grade coal. “What would you do with all the ash?”

“That,” he said, “would require some pretty creative thinking.”

Which brings me to a different plastic bag. This one’s black, tucked into a shelf in my living room, and contains a collection of sewage-related products that I’ve picked up in the course of my reporting. Most can be clearly traced back to sludge — a sample of SlurryCarb-like pellets from a different plant, for example, or a pouch of compost made from sludge and wood chips in an enormous building that used to be an Ikea warehouse. But one of my sewage souvenirs looks like it doesn’t belong: a jar, about the size of a pill bottle, containing tiny black chips the size and shape of a crumbled Oreo cookie. They don’t look or smell like they came from sludge — in fact, they don’t have a smell at all. The chips are glass aggregate, the sparkly material commonly seen on roofing shingles.

Minergy subjects sludge to extremely high temperatures to produce a glass aggregate used in a variety of construction materials.Barb ScheiberThe glass came from a company named Minergy, whose technology is currently being used in a plant at the North Shore Sanitary District in Illinois that won a 2008 Global Grand Project Innovation Award from the International Water Association. Instead of selling dried sludge as fuel, Minergy’s technology uses it as energy for its own process: it combusts pre-dried sludge to create temperatures so high — roughly 2400 to 2700 degrees Fahrenheit — that the minerals that would usually be left over as ash melt into molten glass. When this hot liquid is put into cold water, it shatters, creating the tiny black chips in my jar. It’s as if the sludge consumed itself, avoiding the problem of residual ash by never making it to begin with. The resulting aggregate can be used in shingles, asphalt, concrete, ceramic tiles, sandblasting grit, and a variety of other construction materials.

Minergy subjects sludge to extremely high temperatures to produce a glass aggregate used in a variety of construction materials.Barb ScheiberThe glass came from a company named Minergy, whose technology is currently being used in a plant at the North Shore Sanitary District in Illinois that won a 2008 Global Grand Project Innovation Award from the International Water Association. Instead of selling dried sludge as fuel, Minergy’s technology uses it as energy for its own process: it combusts pre-dried sludge to create temperatures so high — roughly 2400 to 2700 degrees Fahrenheit — that the minerals that would usually be left over as ash melt into molten glass. When this hot liquid is put into cold water, it shatters, creating the tiny black chips in my jar. It’s as if the sludge consumed itself, avoiding the problem of residual ash by never making it to begin with. The resulting aggregate can be used in shingles, asphalt, concrete, ceramic tiles, sandblasting grit, and a variety of other construction materials.

It’s exciting stuff, but the North Shore Sanitary District has run into a very mundane problem: human hair. Flushed down shower drains, incorporated into sludge, hair (and other similarly stringy objects) clogged NSSD’s machinery, which has been temporarily shut down as its operators work on a solution.

That’s the thing about sludge, though — it has tremendous potential for reuse, but a lot of dirty details. To find out how the various technologies stack up, I called James Smith, a senior environmental engineer who’s been at EPA for more than 40 years and has played an important role in shaping biosolids regulations. He said that the “world is watching the outcome of the SlurryCarb start-up,” and he was especially positive about a technology called the Cannibal process, which can reduce the volume of sludge produced by up to 80 percent, partially by getting different types of microbes in the sludge to eat each other. But as for the bigger question of the future of sludge?

“It depends on whose Ouija board you have,” Smith said. “I think what we’re all hoping for is [a process that leaves] very few residuals to deal with, and for whatever we do have to deal with to be the highest quality possible.”

Unfortunately, regardless of which processes emerge, all these alchemies are likely to come with a catch. The solids in wastewater are so diluted that they need to be dried before their energy is recovered, which requires a lot of energy itself. Even worse, while these technologies might prevent toxic chemicals from seeping into farmland, they also prevent nutrients from returning to the soil — a deficit that brings increased use of synthetic fertilizers and their accompanying host of problems. An ideal solution would do one without the other, nourishing the dirt without contaminating it. But until we figure out how to better segregate our waste streams, even the best new techniques will still suffer from this critical, unavoidable flaw.

Tomorrow: In the future, we’ll all haul our own shit.

Part 1: Sludge, farmer’s friend or toxic slime?